I began the process of disassembling this fan a few days ago and it’s been going smoother than I’d expected.

I enjoyed a few of the puzzles it threw in my direction and it’s always nice to be reminded how well thought-out old appliances like these were. There are some extremely well-hidden/pesky grub screws all over the place, so it was important to not rely on brute-force.

I want to say that modern appliances seem “under-engineered” in comparison, but I think that makes it sound like manufacturers nowadays are naïve in their designs when they’re anything but. A product that’s been engineered to last only as long as people expect it to for the price they paid and not a moment more, means the manufacturers get away with low quality, flimsy goods and can even guarantee future sales, provided people think they’ve had their money’s worth.

This fan was designed to never shake itself apart, never suffer from fatigue or stress fractures and never slowly break down electrically from years minor overheating due to components being on the verge of being under-specced.

The first items I removed were the two screw-in oilers. Hopefully it’s evident from the photos what a mess these are in. The wick is hard and they’re caked in black, waxy wax.

The diagonal knurling on the brass body is unusual and attractive. It looks like the knurling tool might have been set at an angle to the piece, leaving a sharp, triangular knurl, where the tool has bitten deeper on one side.

I can’t wait to get these clean, but it’s really important to me that my efforts don’t erode the crispness of that knurling.

The next to be removed was the top handle. Two easy screws that had already slightly loosened. I could see that the screws had already been damaged from someone using the wrong screwdriver – something that I’m really particular about, much to the displeasure of literally everyone who has the misfortune of hearing me talk about it.

You can see below how the screw has been damaged. I’ll attempt to push the displaced metal back into place after I’ve cleaned them.

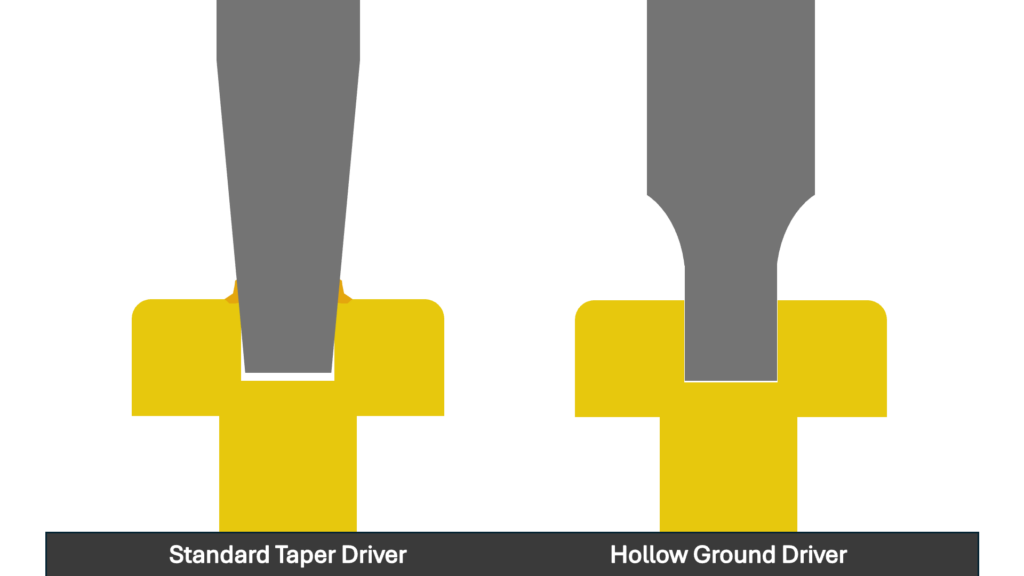

These soft brass screws all need hollow-ground drivers to prevent the screw head from being deformed.

The top handle and it’s screws get labelled and stored in the organiser. I’ve measured each screw as they’re removed just in case any get misplaced or mixed in with others.

The next candidates for removal were the retaining screws for the cage bracket. Although the cage is missing, the screws were all still present. Sadly one was bent. This may be a candidate for replacement, rather than repair.

After removing the screws on the rear gearbox plate, I saw a grease/oil nipple and a circular plug that looked to be a really tight fit. The plug evaded my first efforts to remove it, but after giving the top knob a few turns back and forth, the plug started to pull out. Due to all the grease, it there was a pretty strong vacuum resisting my pull. But it came free eventually.

The gearbox was full of hard, waxy grease. I picked some of this out, just out of curiosity. I’ll give it a proper clean once it’s fully disassembled.

Once this part was out, I was able to get enough leverage with my fingers to unscrew the locking nut that would have required me to make a custom driver with a notch in it. I was pleased about this, but I’ll likely make a driver ready for when I need to reassemble.

Inside the gearbox, you can see one of the worm gears. It appears to be in good condition.

That’s it for now, I’ve broken the fan down further than this, but this is all I have time for today.

Leave a Reply